What is grain direction, and why it's important, when ordering 3D WALL PANELS?

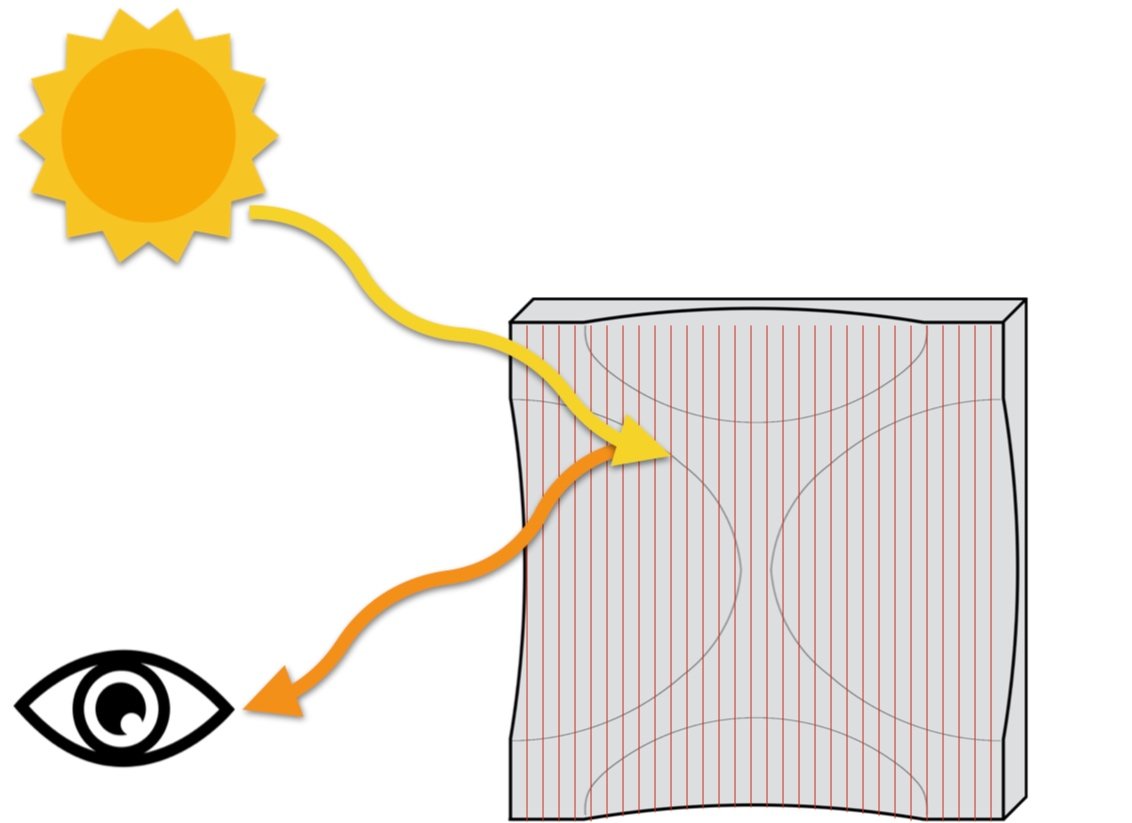

Would you believe me, if I told you that the two, above shown pictures are from the same pair of veneer wall panels? Not only that, but all the panels on this wall were made of the same type of veneer, the same colour, and received the same post-production treatment.

THEN WHY DO THEY DIFFER SO MUCH? AND WHY JUST FROM CERTAIN ANGLES?

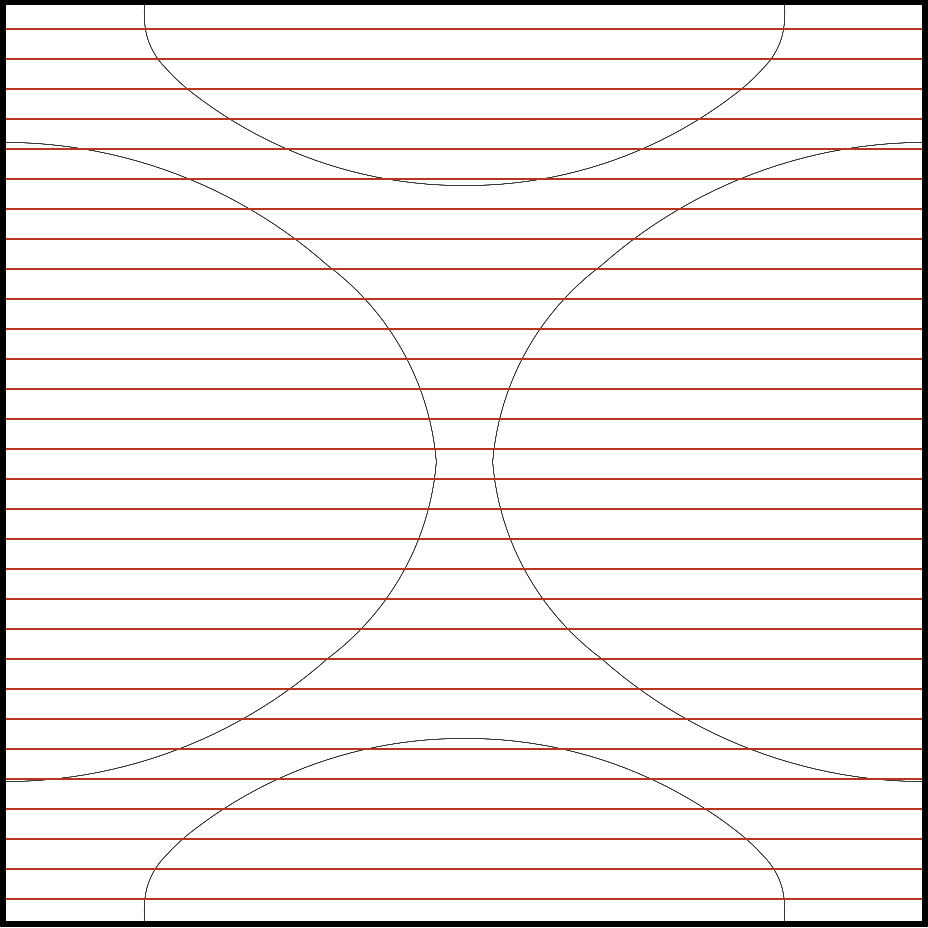

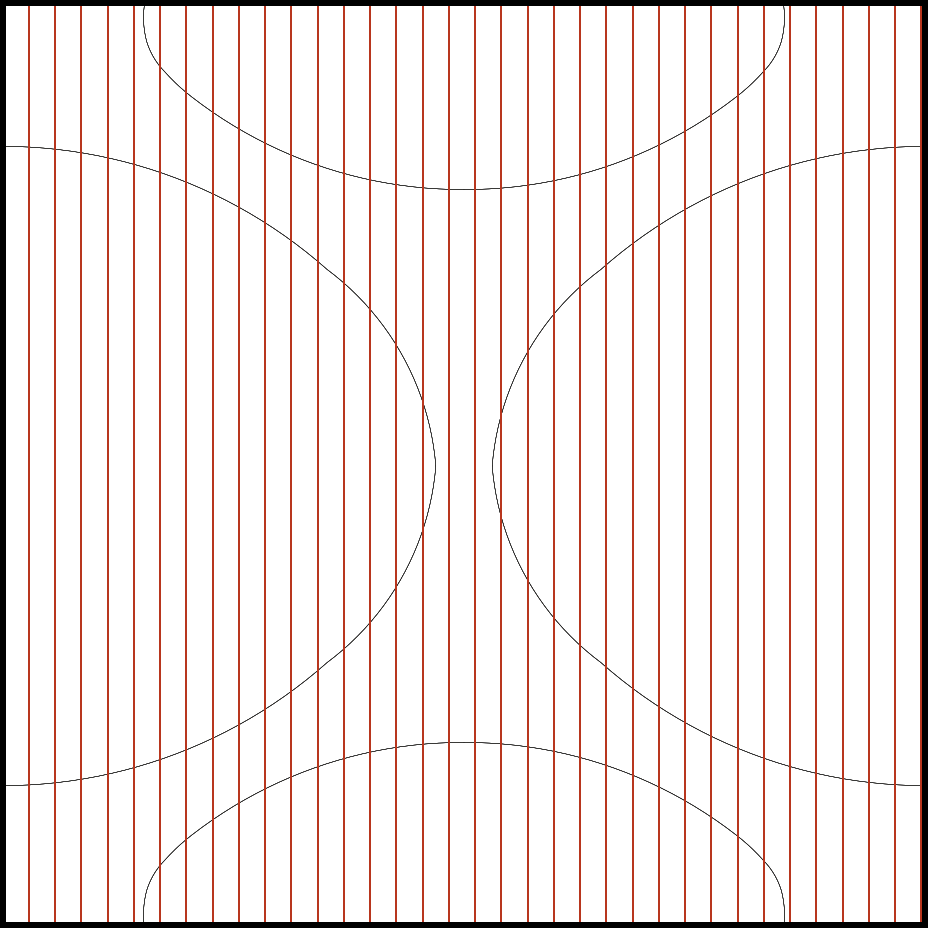

The answer lies in our title: Grain direction. The only difference is that the left panel has horizontal grain direction, while the panel to its right has vertical grain direction.

Also: The difference only becomes visible from certain angles. Lighting can also play a role in either masking, or displaying this difference, especially in case of 3D wall panels.

OK. BUT WHAT IS GRAIN DIRECTION EXACTLY?

In woodworking, grain direction refers to the longitudinal, or vertical axis of the trunk, along which the structural cells are elongated. It is the texture seen on the cut surface of a piece of wood.

In layman’s terms: they’re the lines that go along the surface of wood, when you cut it.

WHY DOES THIS CHANGE IN THEIR LOOKS HAPPEN AT ALL?

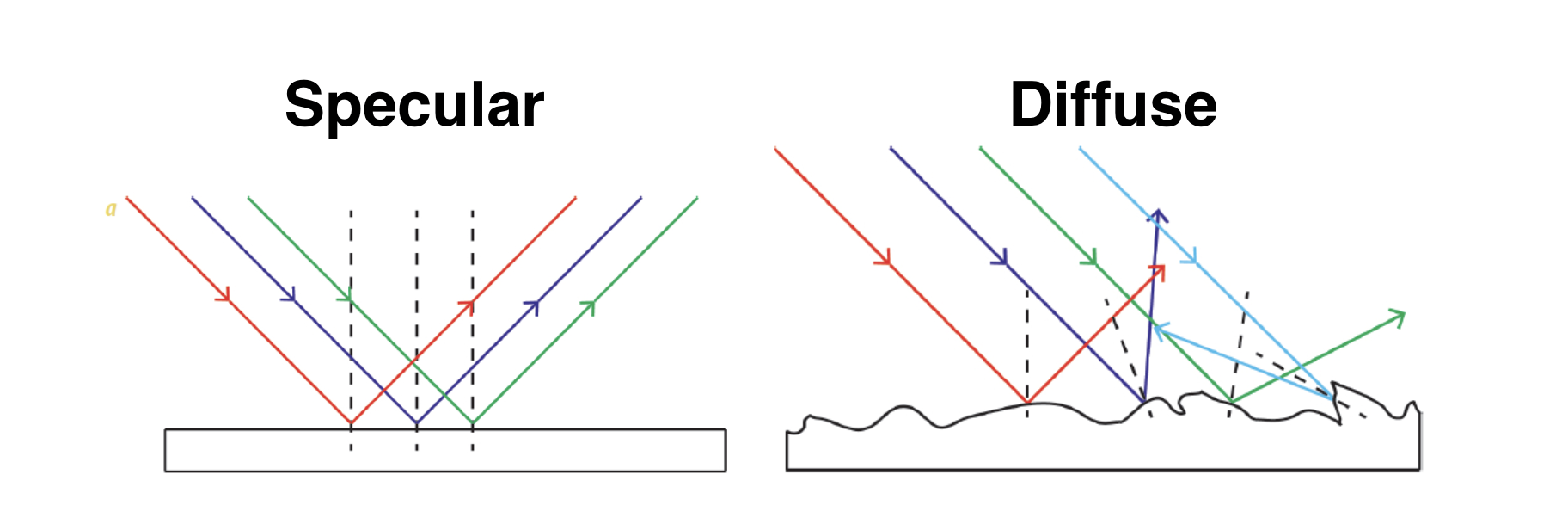

The trick is in how light reflects off of veneer surfaces.

Since a slice of veneer isn’t exactly a smooth or mirror-like surface, when light hits it, it refracts in a term they call “Diffuse reflection”, meaning that different parts of the object reflect sources of light in different directions.

THIS is where grain direction comes into play.

Since the grains add another layer of unevenness to the surface of the veneer (Even if it receives a coating or finish in the end) it also affects how light reflects from the object.

This causes certain wavelengths of light to reflect differently, causing the panel to appear as one of different colour from certain angles.

This not only warrants a special mindset when deciding how and where to illuminate veneer panels from, but can also cause a strong dissonance between what the client thought he was buying, and what he got in the end.

HOW CAN I BEST AVOID IT?

Since grain direction is a result of the production of the veneer, your best bet is that you don’t wait and try to account for this yourself afterwards, but rather reaching-out to your professional carpenter / woodworker and expressing your end-result needs in-advance.

You don’t have to brief them on the technical end, they’ll know what you’re talking about.

For example: In case of 3d wall panels made from veneer, we would advise that the best solution for this is to keep the grain directions uniform. All the panels should be either vertical or horizontal. No mixing the two. If that happens, your panels would already be prone to this effect.

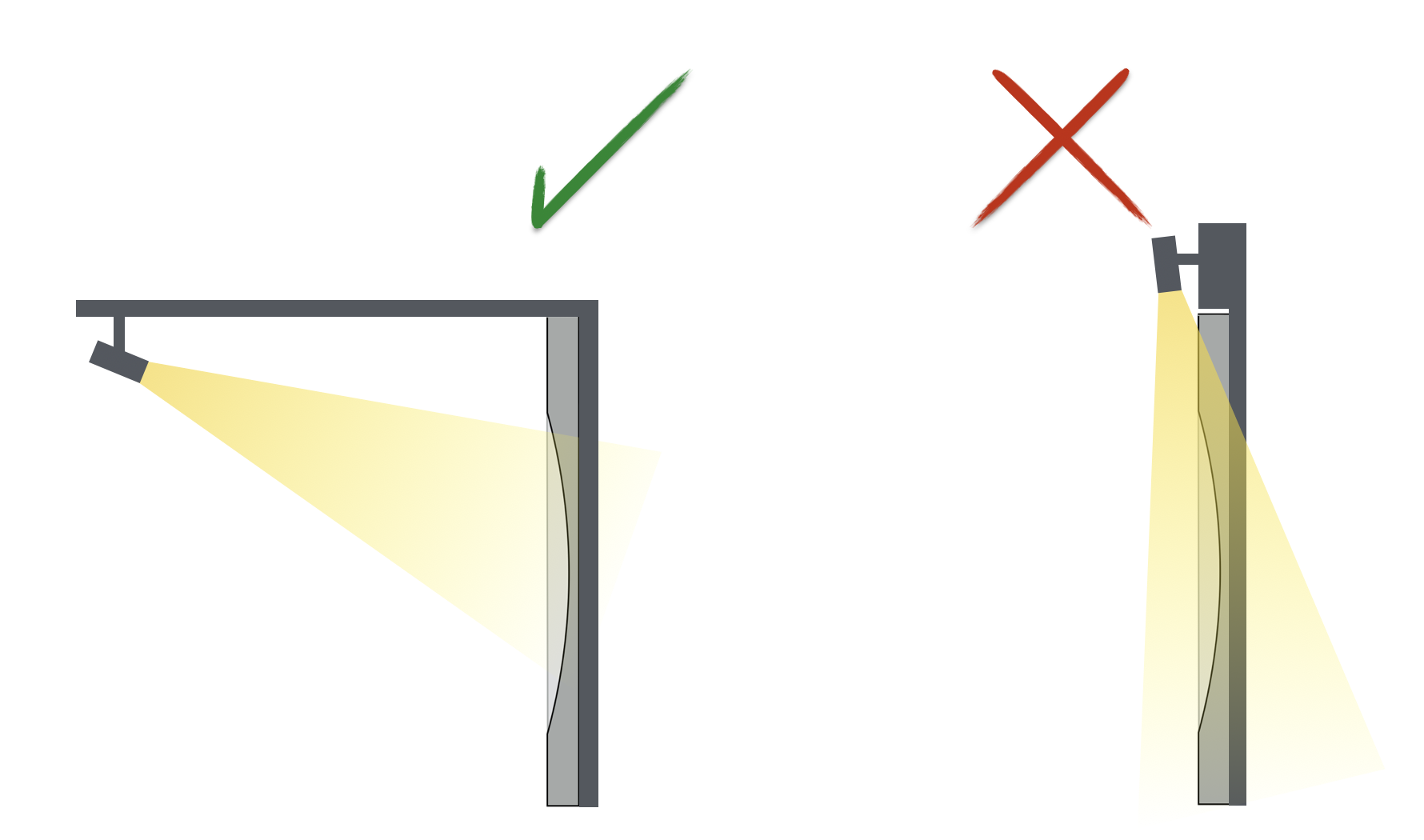

Another factor is lighting. If you already have a wall with different grain directions, and switching, or realigning them isn’t possible anymore, you can smooth-out the strong contrast between the two by lighting them from certain angles. Usually the angle of lighting that brings out the difference the most is one from directly above the panels.

SUMMARY:

Since clients aren’t experts in carpentry or optics (nor should they have to be), brands like us have to be extra careful and proactive in communicating certain properties of our products, and if possible, informing our clients about unique aspects of the materials we work with. Not only to avoid confusion and conflict regarding orders, but also to best inform our general audience of the small things that might be easily overlooked by a customer, but can strongly affect the end result of carpentry projects. To strive towards a better understanding between clients and sellers.

If you would like to ask us any other questions regarding veneer, you can do so any time by reaching out to us. Our friendly staff is always happy to help, no matter the qestion!

We hope you had an interesting read! - and we’ll be back soon with more! :)

-MOKO Interior Team